Model Y Equipment Engineering

For this project, I was responsible for designing the cooling system for the Berkeley Formula Racing 2020 car (B20).

I was challenged with selecting an appropriate radiator and designing and manufacturing mounting, ducting, and plumbing.

One of the biggest design changes for the 2020 car was our updated engine package, a KTM 450SXF.

With an extra 100cc of displacement and up to 20 more horsepower, I needed to meet a higher

significantly heat rejection rate than was achieved on B19.

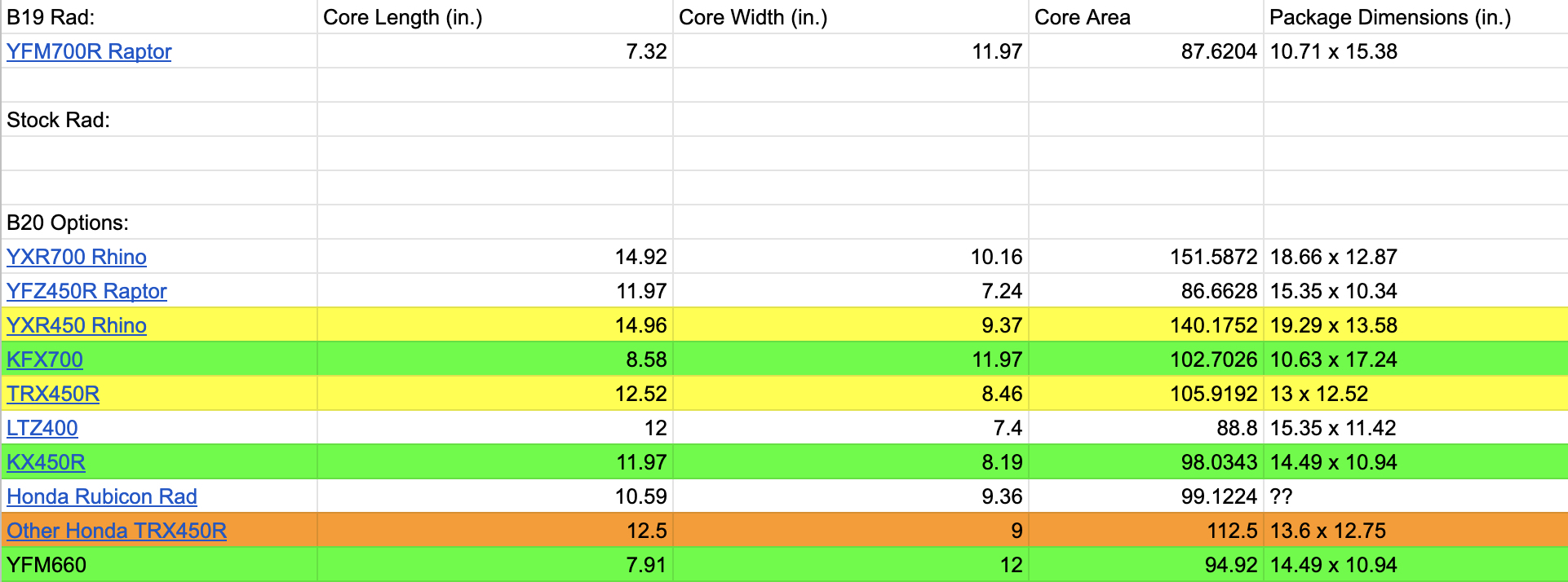

Quantifying increased heat production in the 450 proved to be a challenge; basic heat convection

calculations pointed to a frontal surface area increase requirement of about 12%. Simple scaling calcs

(B20 horspower / B19 horsepower) pointed to an increase of 9%. After reading some literature from

other formula teams, I decided to go with a Mishimoto ATV radiator that had a frontal area increase of

roughly 10% over B19, with most other factors (number of coolant passes, fin density) kept the same.

With a radiator selected and a rough model inserted into Solidworks, I set about designing a

mounting system. I kept my first iterations roughly similar to B19, with easily manufacturable

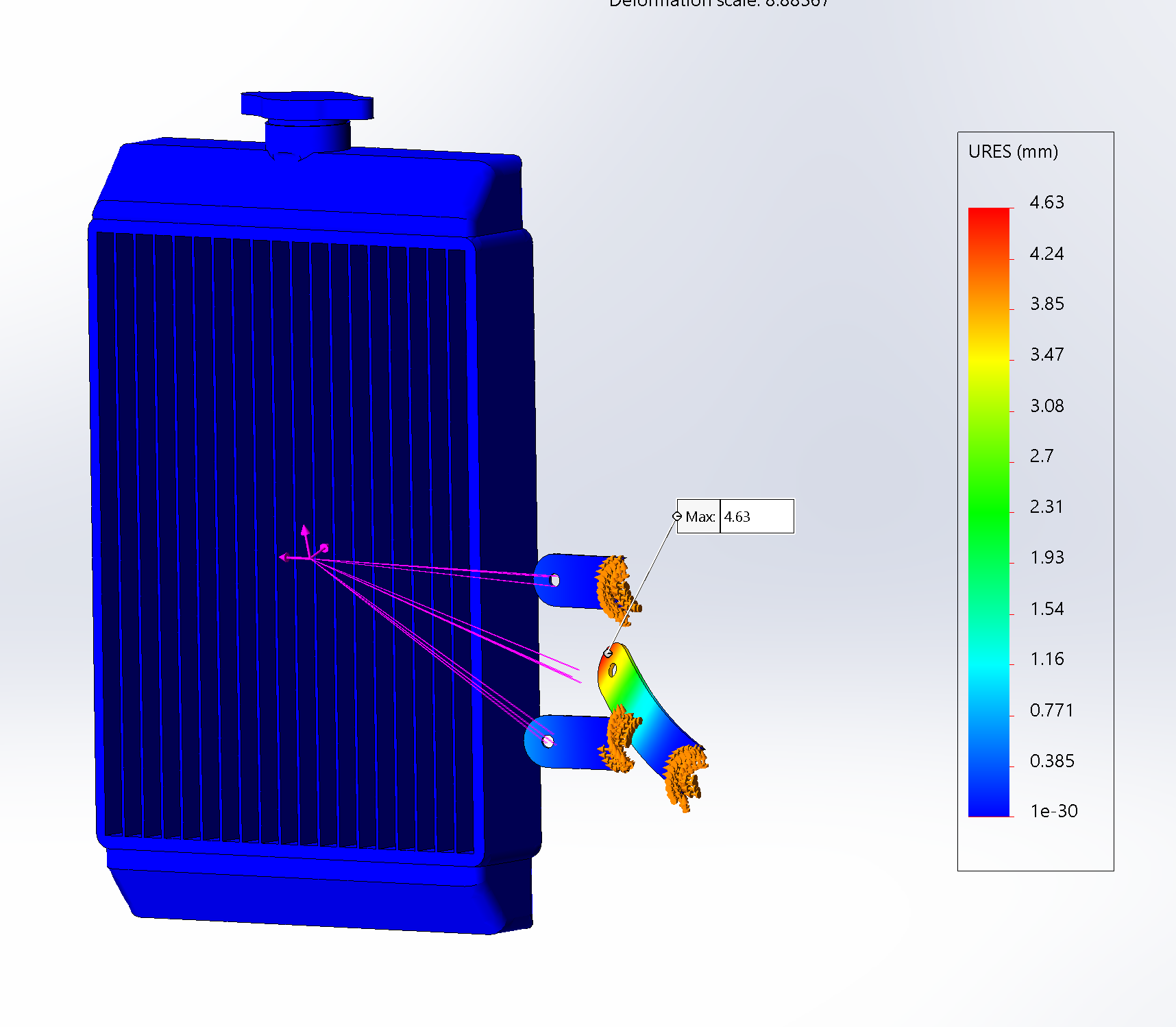

aluminum tabs that bolted to corresponding steel tabs on the chassis. In order to (1) ensure compliance and (2)

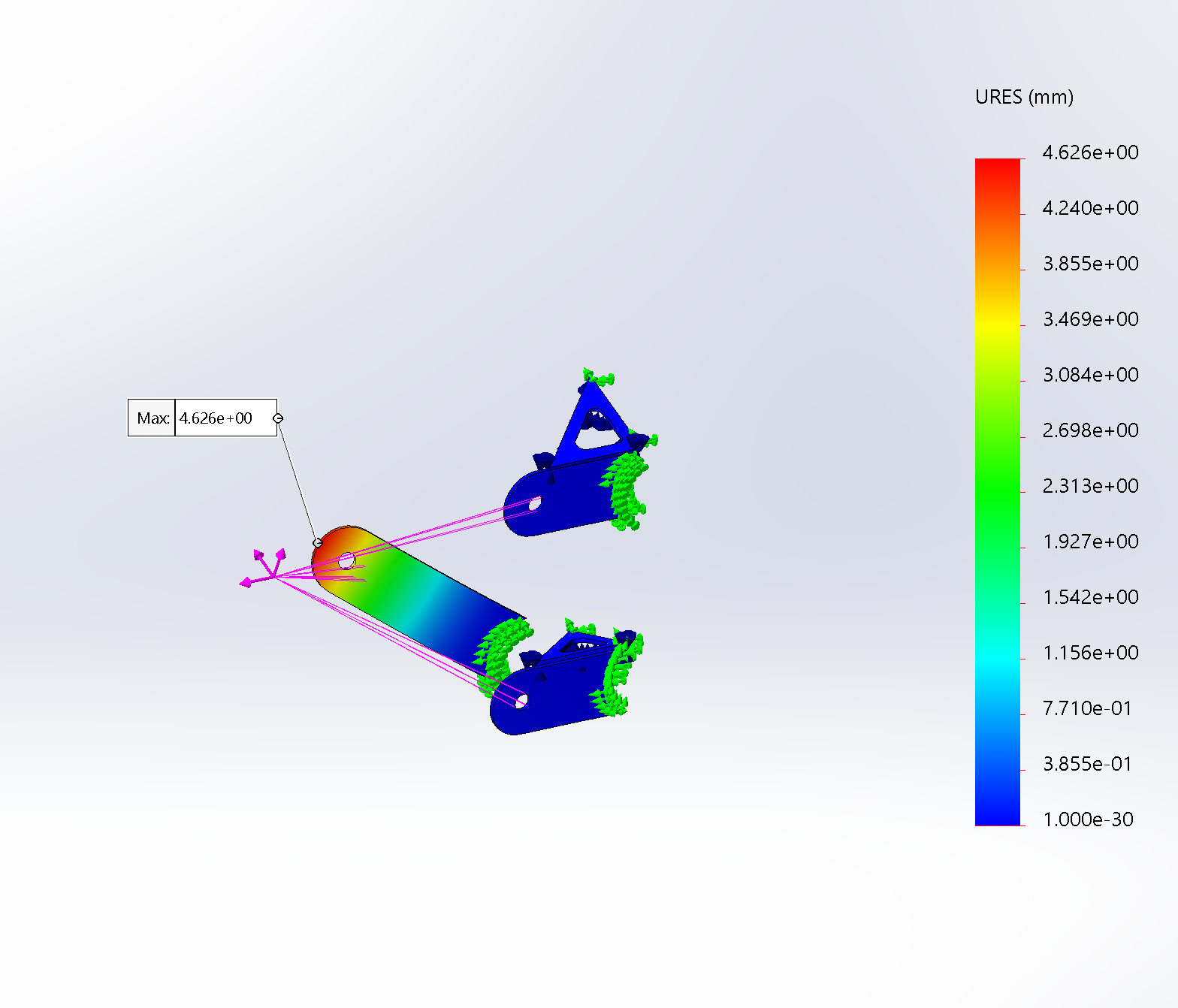

compare stiffness to B19, I ran static FEA’s under worst-case loads: 1.5G acceleration, 2G cornering, and 3G bumps.

2019 Displacement:

I initially planned to go with three sets of tabs, two on the chassis, and one on the far side

of the radiator connected to the sidewing. Our aero team, however, decided not to run sidewings for

the 2020 car, so I came up with a new design using a rod to connect the outside edge of the radiator from

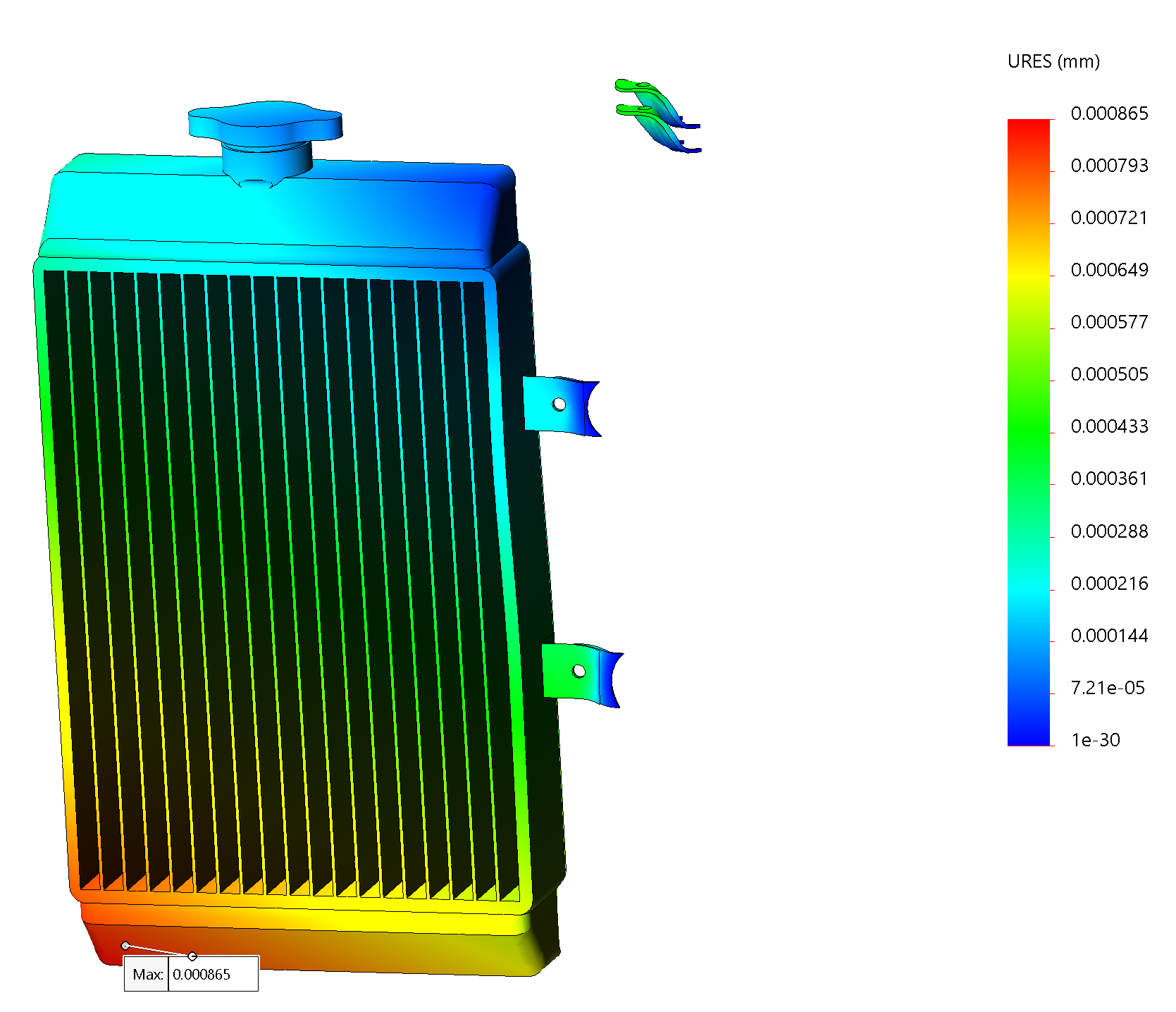

deflecting. FEA’s showed significant improvement, less than a millimeter of deflection.

2020 Displacement:

My initial design relied on a solid tube welded to the bottom edge of the radiator. After

consulting with my team lead, we decided to move the rod to the top of the radiator (allowing the

radiator to be lowered as much as possible) and swap it out for a more aesthetically pleasing, and

modular, tie rod.

Finally, I designed a fan shroud to be molded out of carbon fiber. I intend to consult some alumni as well

as run some CFD’s to validate the necessity of a shroud before manufacturing, as it could be counterproductive

to always channel air to a fan that isn’t always running.

After running through multiple design reviews with formula alumni, the cooling design was finalized

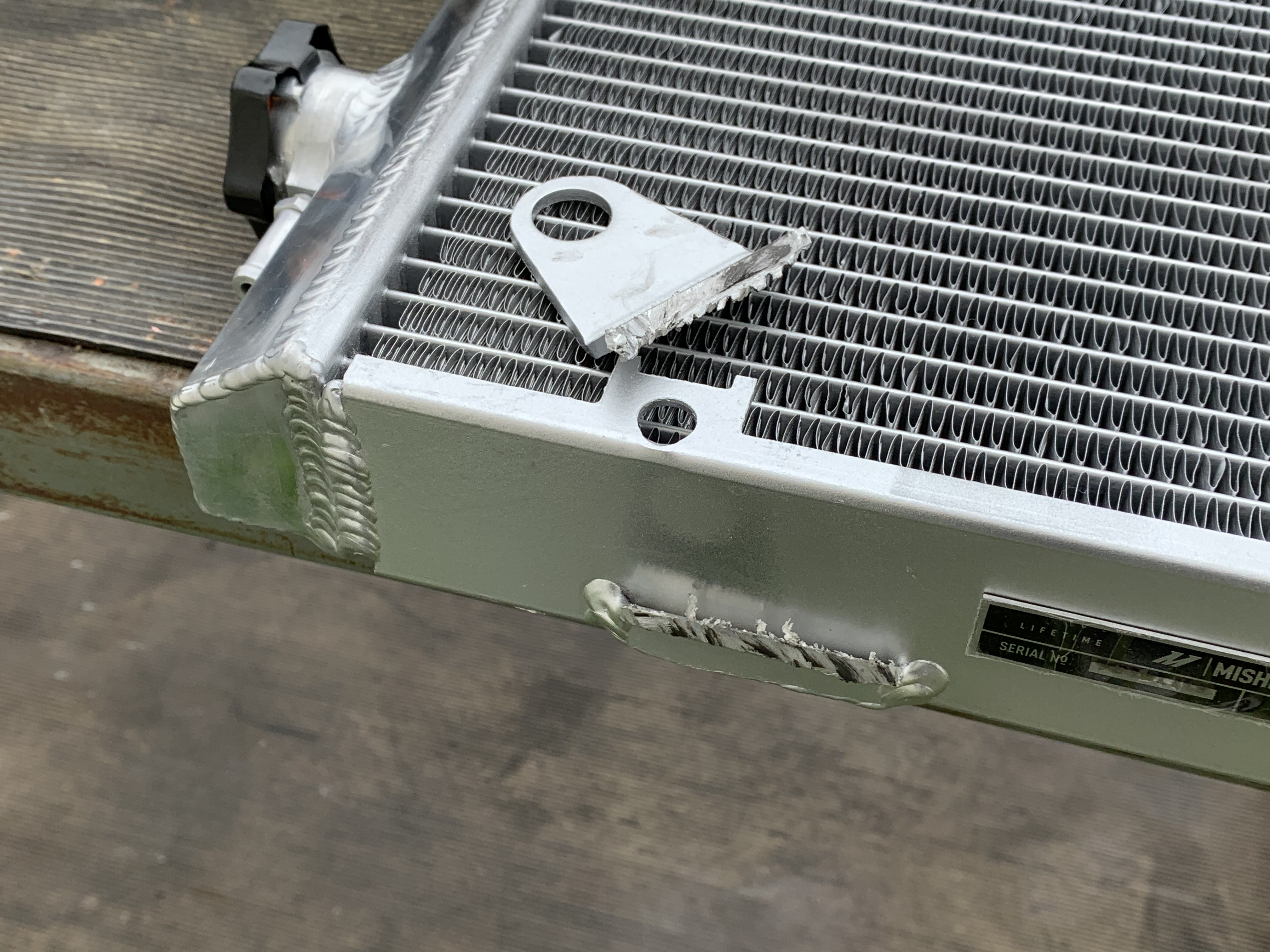

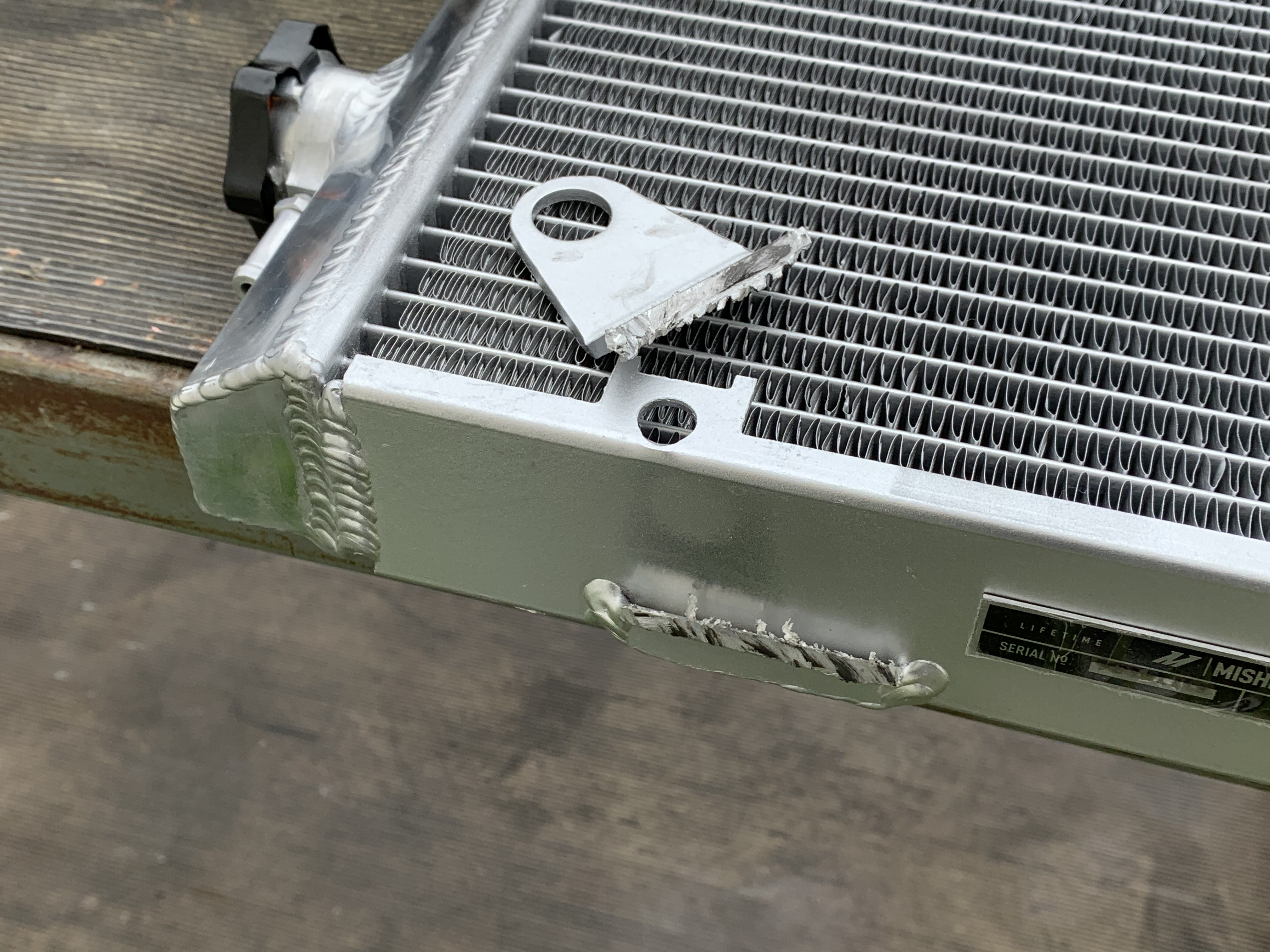

and I began manufacturing. After acquiring the radiator via a Mishimoto sponsorship, I cut off the

factory mounting tabs and locator pin.

Using the tube profiles I created in Solidworks, I laser cut steel tabs for the chassis, ground

down the edges, and welded them on.

I then cut two new tabs out of 60 thou aluminum for the sides of the radiator, bent them in

a vice, used the chassis tabs to align them vertically, and tacked them on.

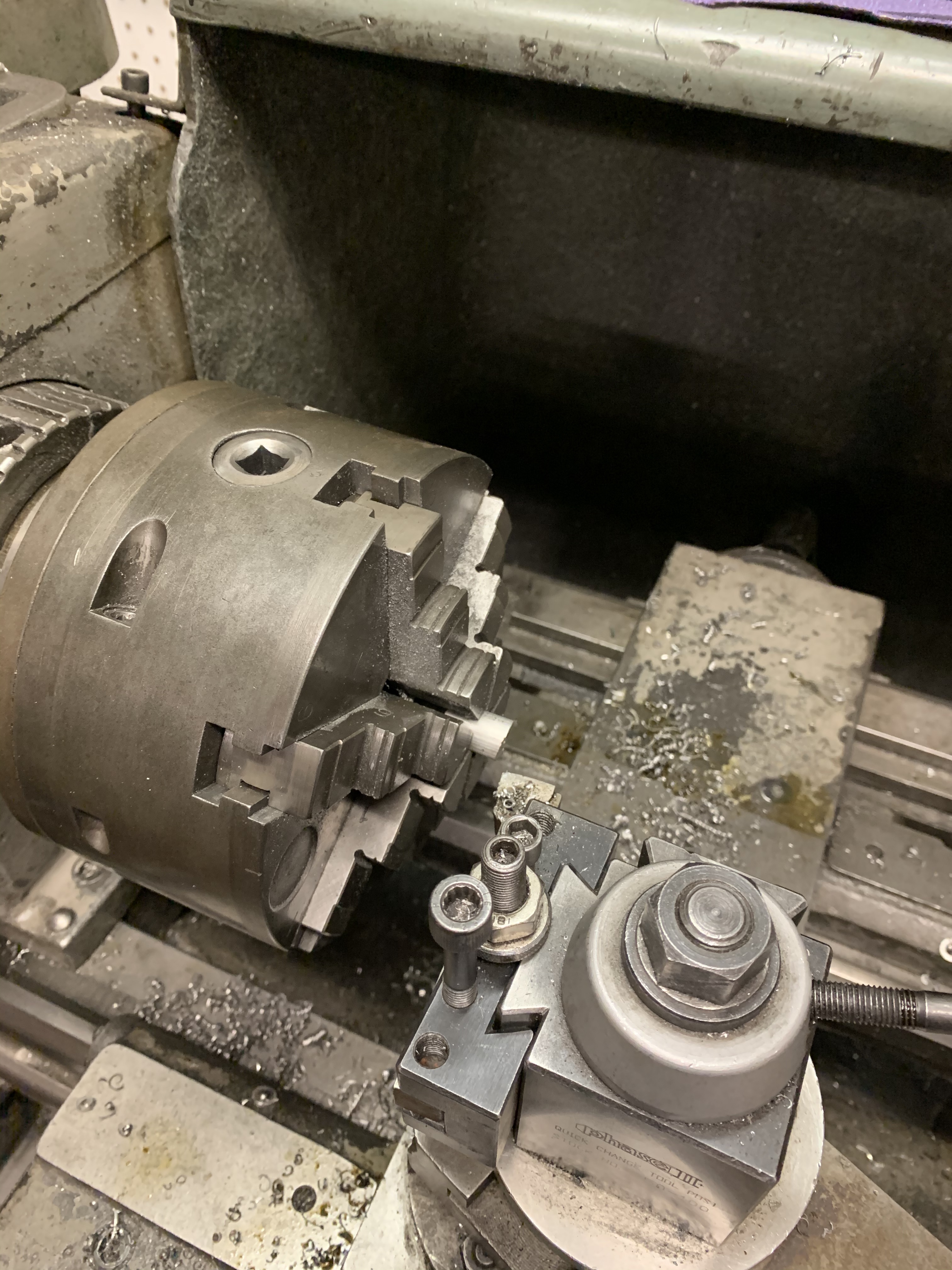

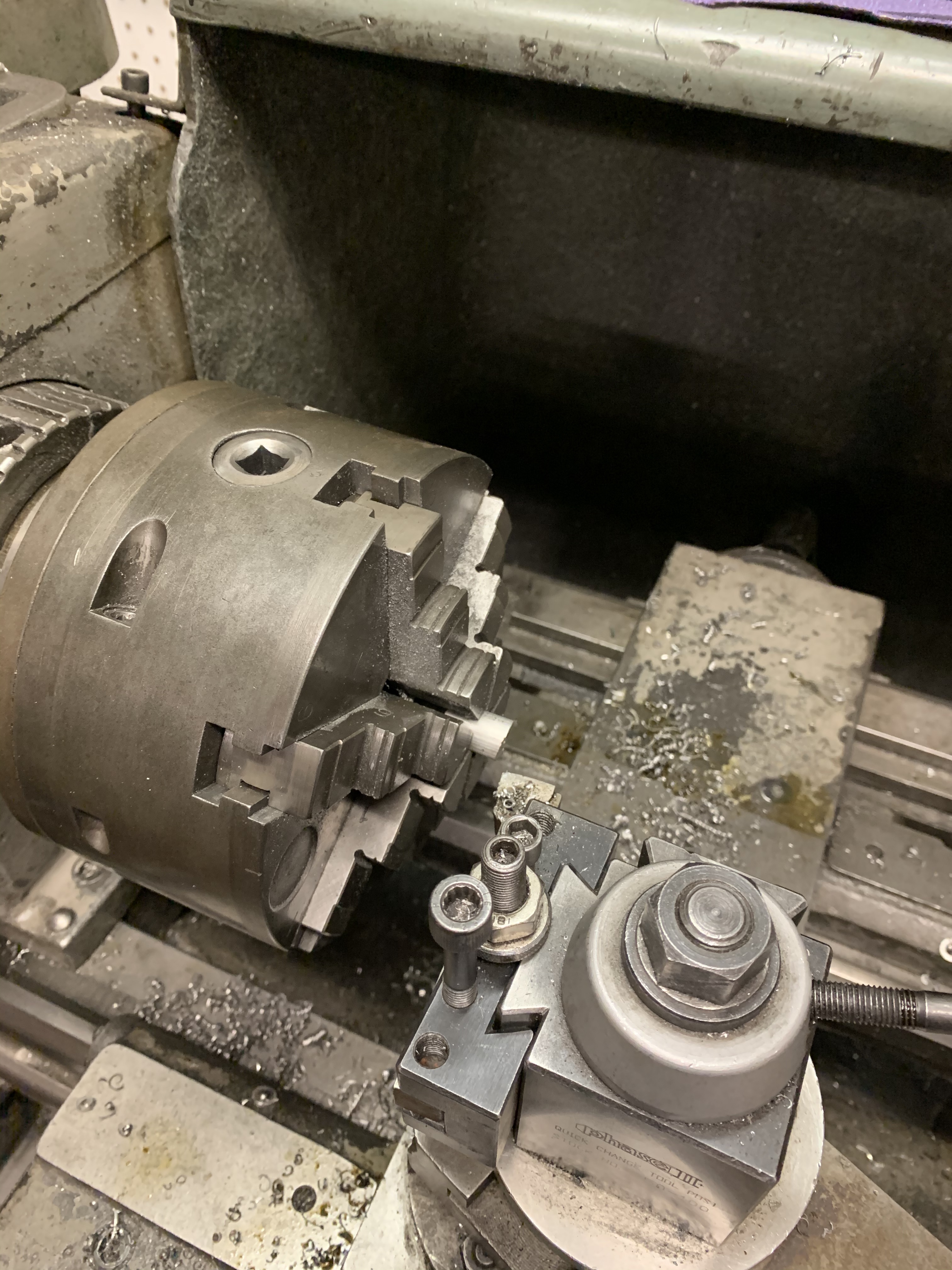

For the rod assembly, the main challenge was machining threaded inserts.

I first used a lathe to drill and tap through a chunk of solid 0.5”

aluminum stock, then cut the piece in half with a bandsaw, and cut down

the diameter so each piece could slide inside 0.5” tube. Lastly, I milled flats onto each

insert so that the rod could be tightened once on the car.

After welding the inserts into the tube, everything was ready to be fit on the newly-painted

B20 chassis.

For this project, I was responsible for designing the cooling system for the Berkeley Formula Racing 2020 car (B20). I was challenged with selecting an appropriate radiator and designing and manufacturing mounting, ducting, and plumbing.

One of the biggest design changes for the 2020 car was our updated engine package, a KTM 450SXF. With an extra 100cc of displacement and up to 20 more horsepower, I needed to meet a higher significantly heat rejection rate than was achieved on B19.

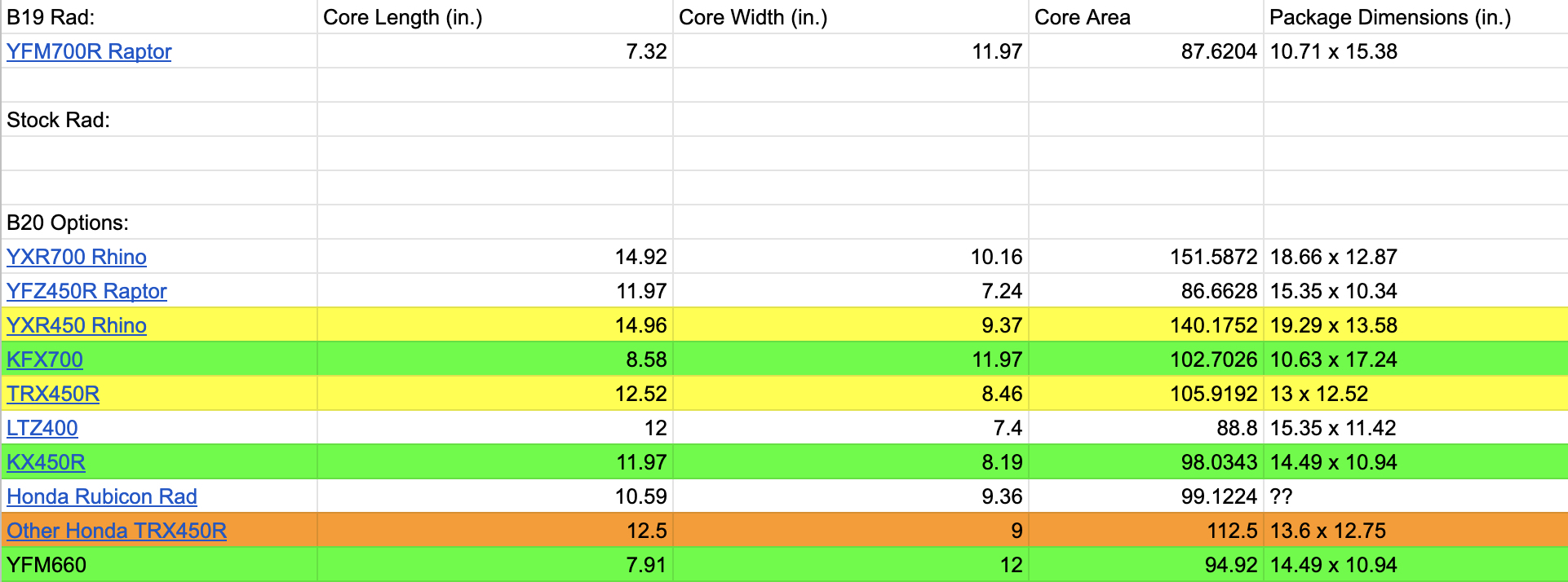

Quantifying increased heat production in the 450 proved to be a challenge; basic heat convection calculations pointed to a frontal surface area increase requirement of about 12%. Simple scaling calcs (B20 horspower / B19 horsepower) pointed to an increase of 9%. After reading some literature from other formula teams, I decided to go with a Mishimoto ATV radiator that had a frontal area increase of roughly 10% over B19, with most other factors (number of coolant passes, fin density) kept the same.

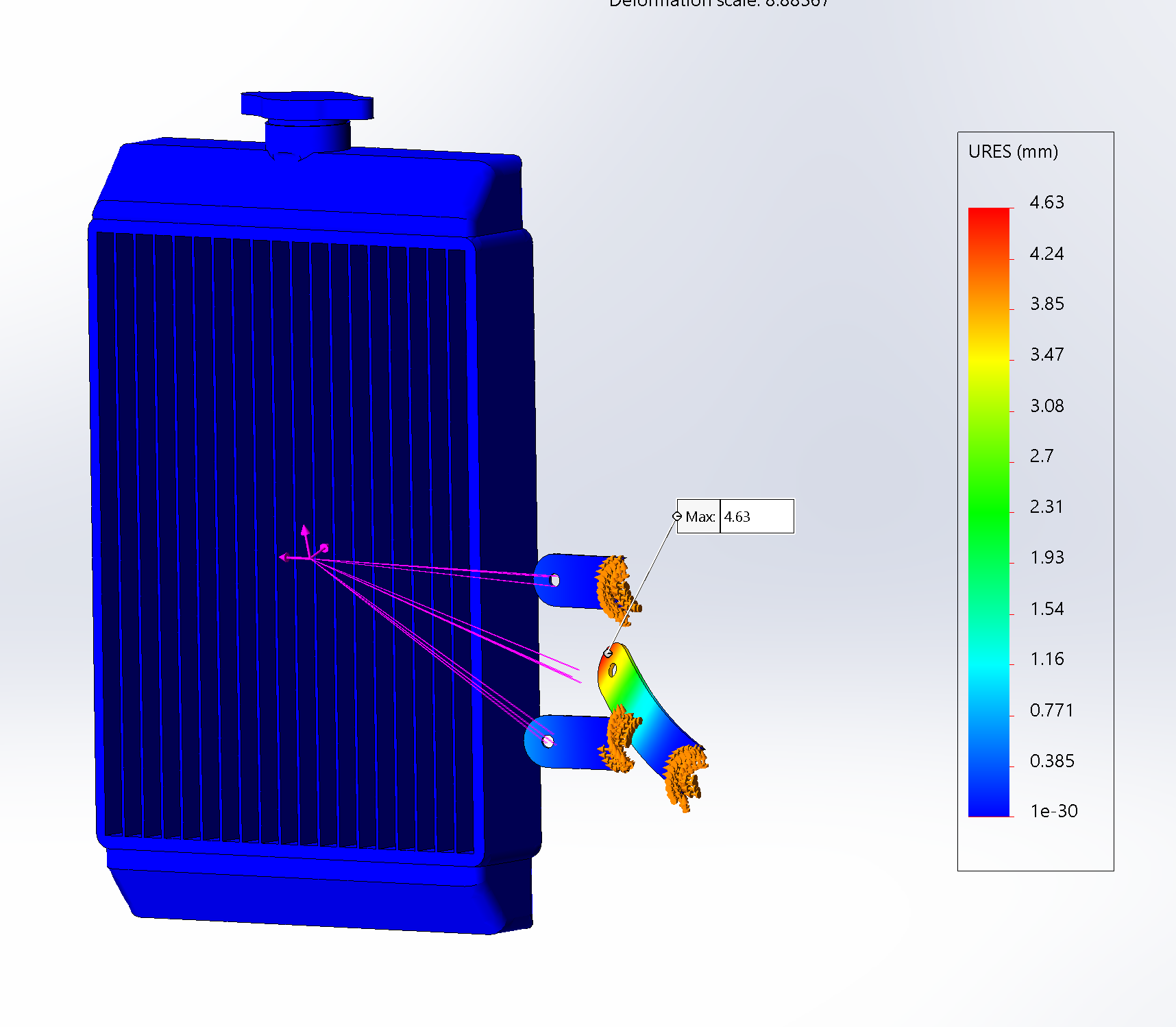

With a radiator selected and a rough model inserted into Solidworks, I set about designing a

mounting system. I kept my first iterations roughly similar to B19, with easily manufacturable

aluminum tabs that bolted to corresponding steel tabs on the chassis. In order to (1) ensure compliance and (2)

compare stiffness to B19, I ran static FEA’s under worst-case loads: 1.5G acceleration, 2G cornering, and 3G bumps.

2019 Displacement:

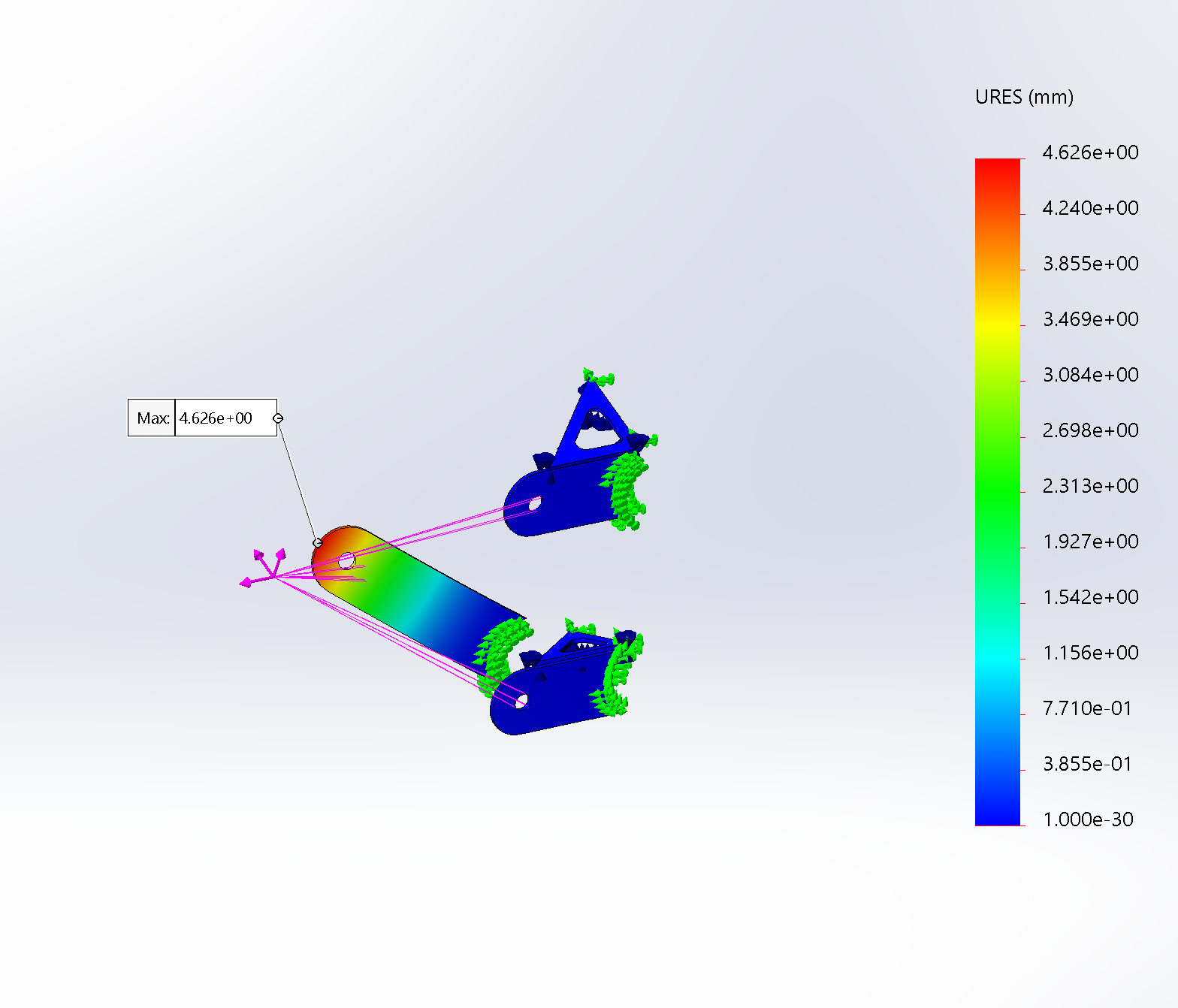

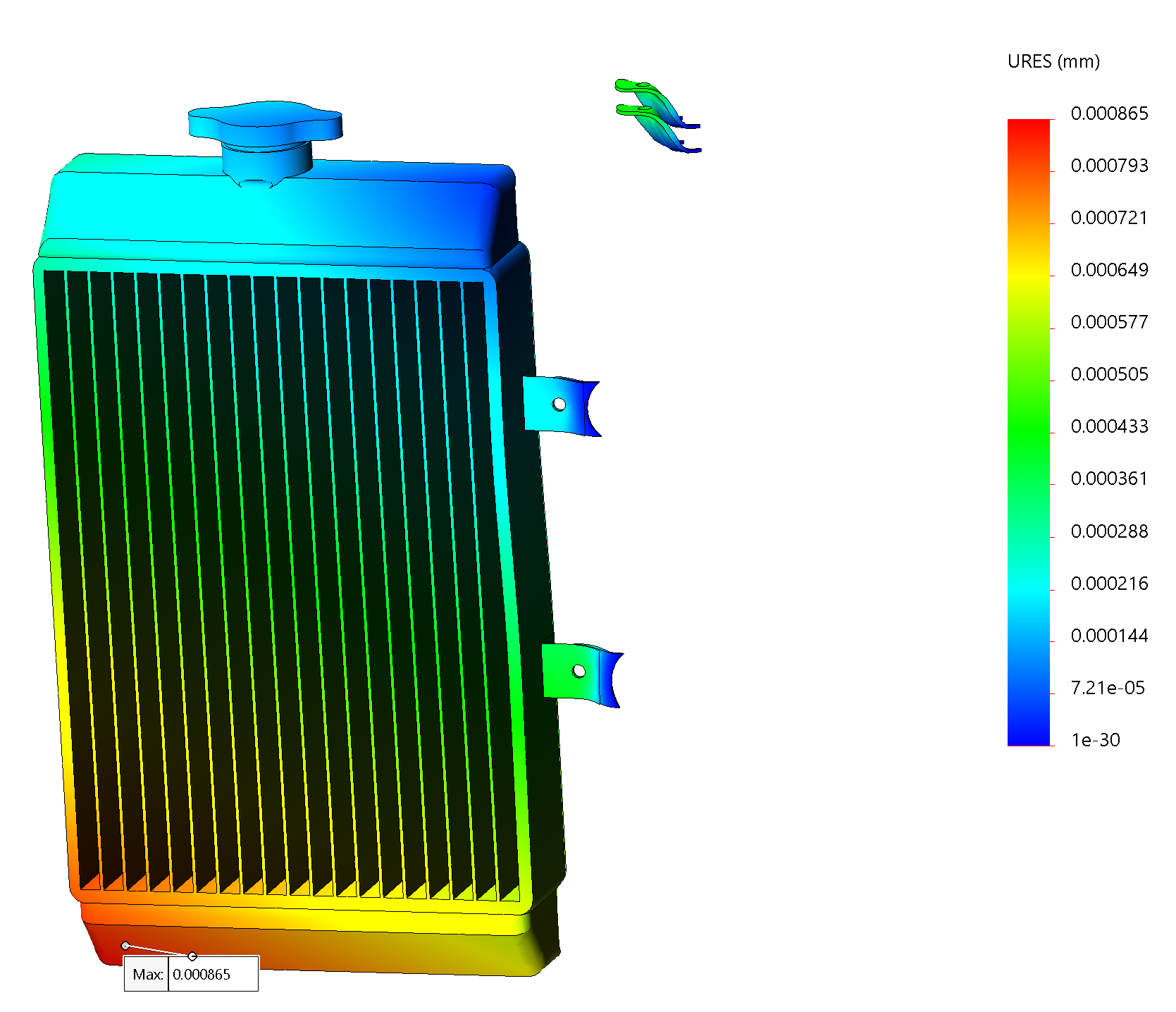

I initially planned to go with three sets of tabs, two on the chassis, and one on the far side of the radiator connected to the sidewing. Our aero team, however, decided not to run sidewings for the 2020 car, so I came up with a new design using a rod to connect the outside edge of the radiator from deflecting. FEA’s showed significant improvement, less than a millimeter of deflection.

2020 Displacement:

My initial design relied on a solid tube welded to the bottom edge of the radiator. After consulting with my team lead, we decided to move the rod to the top of the radiator (allowing the radiator to be lowered as much as possible) and swap it out for a more aesthetically pleasing, and modular, tie rod.

Finally, I designed a fan shroud to be molded out of carbon fiber. I intend to consult some alumni as well as run some CFD’s to validate the necessity of a shroud before manufacturing, as it could be counterproductive to always channel air to a fan that isn’t always running.

After running through multiple design reviews with formula alumni, the cooling design was finalized and I began manufacturing. After acquiring the radiator via a Mishimoto sponsorship, I cut off the factory mounting tabs and locator pin.

Using the tube profiles I created in Solidworks, I laser cut steel tabs for the chassis, ground down the edges, and welded them on.

I then cut two new tabs out of 60 thou aluminum for the sides of the radiator, bent them in a vice, used the chassis tabs to align them vertically, and tacked them on.

For the rod assembly, the main challenge was machining threaded inserts. I first used a lathe to drill and tap through a chunk of solid 0.5” aluminum stock, then cut the piece in half with a bandsaw, and cut down the diameter so each piece could slide inside 0.5” tube. Lastly, I milled flats onto each insert so that the rod could be tightened once on the car.

After welding the inserts into the tube, everything was ready to be fit on the newly-painted B20 chassis.